Industrial tablet computer in the packaging industry applica

With the continuous progress of society and the rapid development of various industries, the packaging industry has also been rapidly developed. Now, the trend of machines replacing workers is more and more fierce, packaging industry is no exception, take the output of packaging industry, ten years ago, the output of packaging machinery in our country has reached more than 500,000 units/year. Under the background of rapid development of automation control, industrial tablet computer has also been widely used in packaging industry. So today, micro embedded Xiaobian and you to talk about the industry tablet computer application scheme in the packaging industry, I hope to help you.

For packaging machinery, different ingredients, different packaging materials, different packaging containers and other packaging requirements. In the packaging process, the control system needs to make the machine high-speed, accurate and stable operation. Provide the accurate position of the machine to correct the error caused by friction or vibration during the transmission process.

Industrial tablet computer in its powerful processing capacity, can accurately handle different packaging instructions, and in the production speed, mechanical performance, noise pollution and other indicators, are the previous machinery can not be matched.

Today, the need for highly flexible operation and continuous drive to maximize capacity presents great challenges and opportunities for suppliers. New motion control products are becoming more powerful and compact, and new architectures can provide comprehensive technical solutions for a wider range of packaging machinery applications.

Here is a series of application profiles to show the continued progress of automation and motion control solutions and the increasingly better overall solutions available for packaging machinery.

Solutions for Industrial Tablets:

Automatic packaging is a very complex process, even in the era of manual packaging, packaging work also needs to go through multiple processes. Including but not limited to weighing, sorting, film shrinkage (inner packaging)/filling, coding, packing and other steps.

This requires industrial tablets to have strong computing power and control ability.

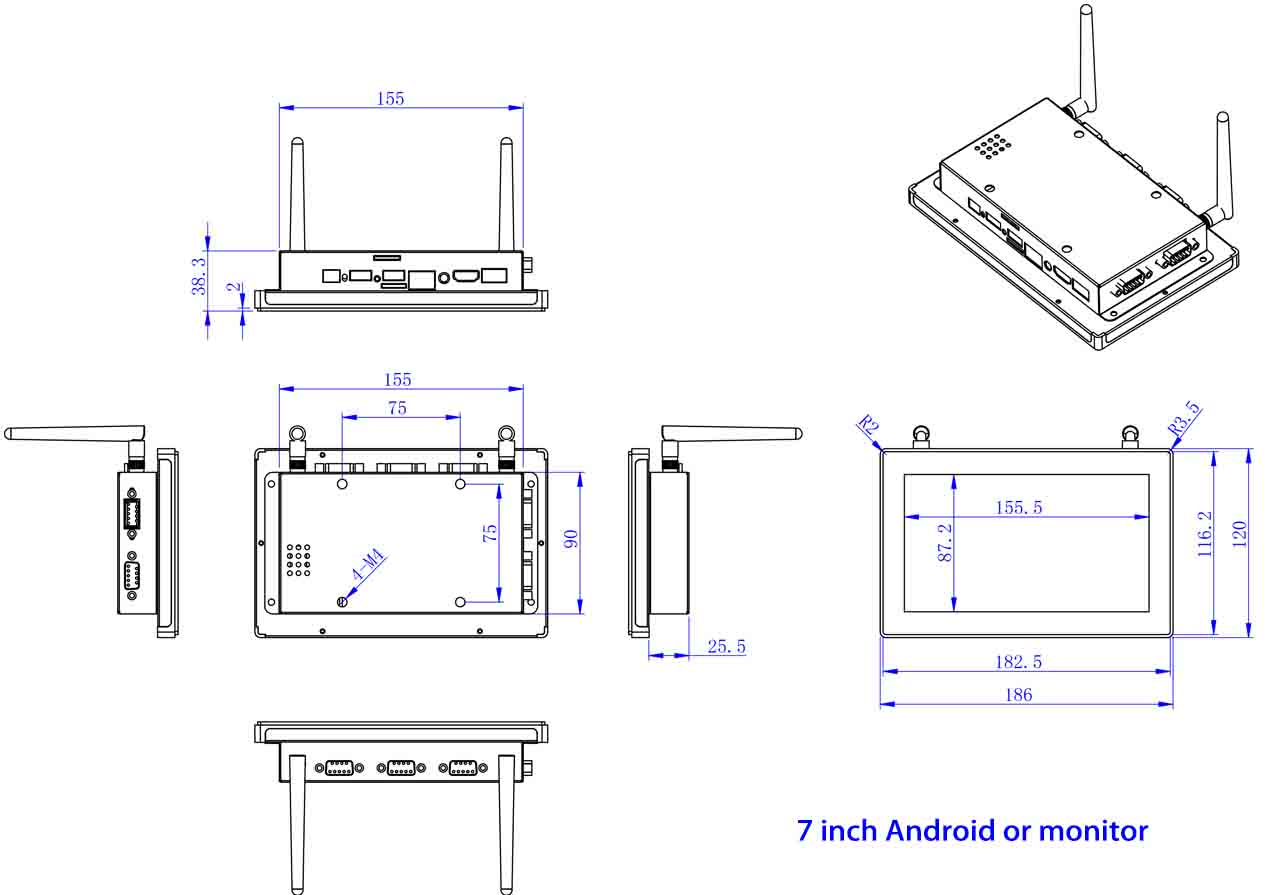

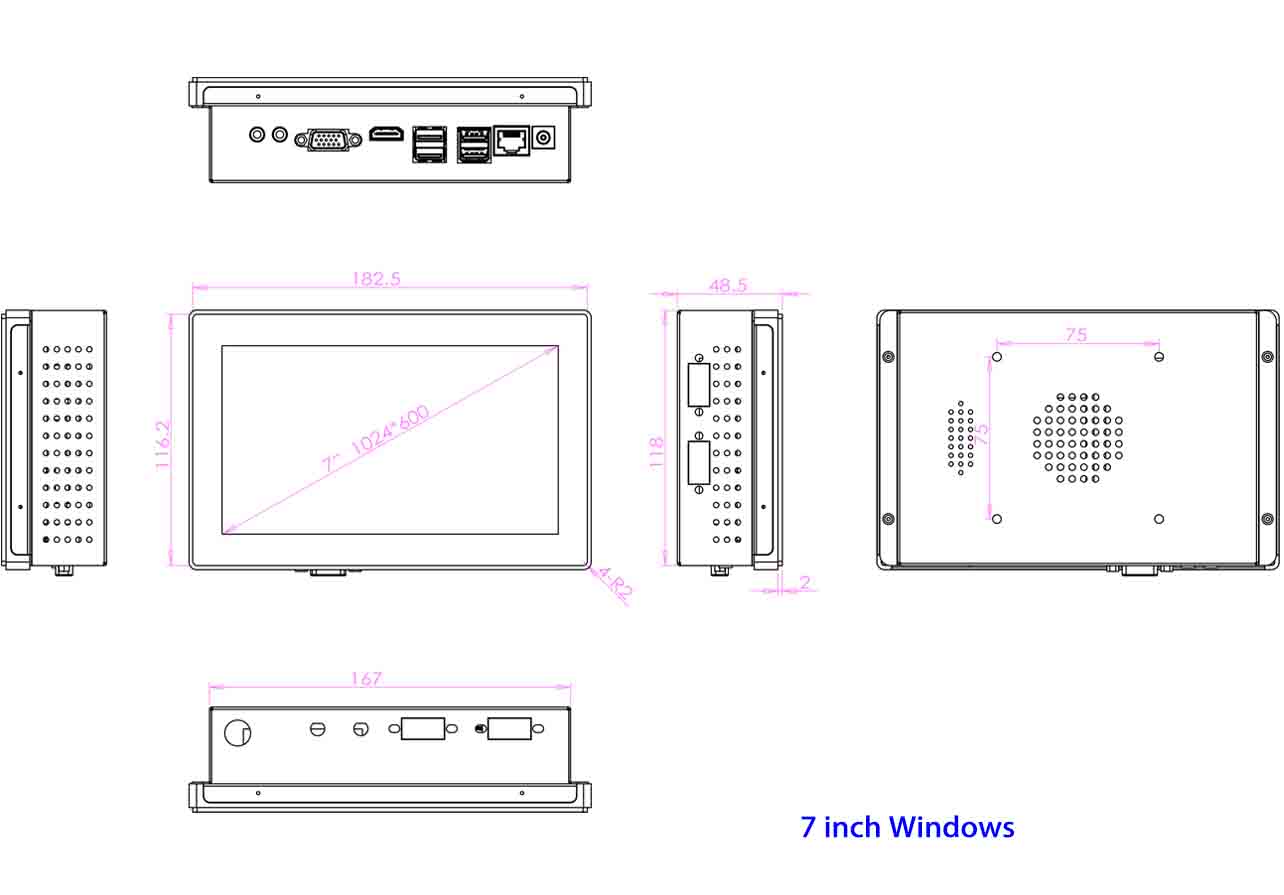

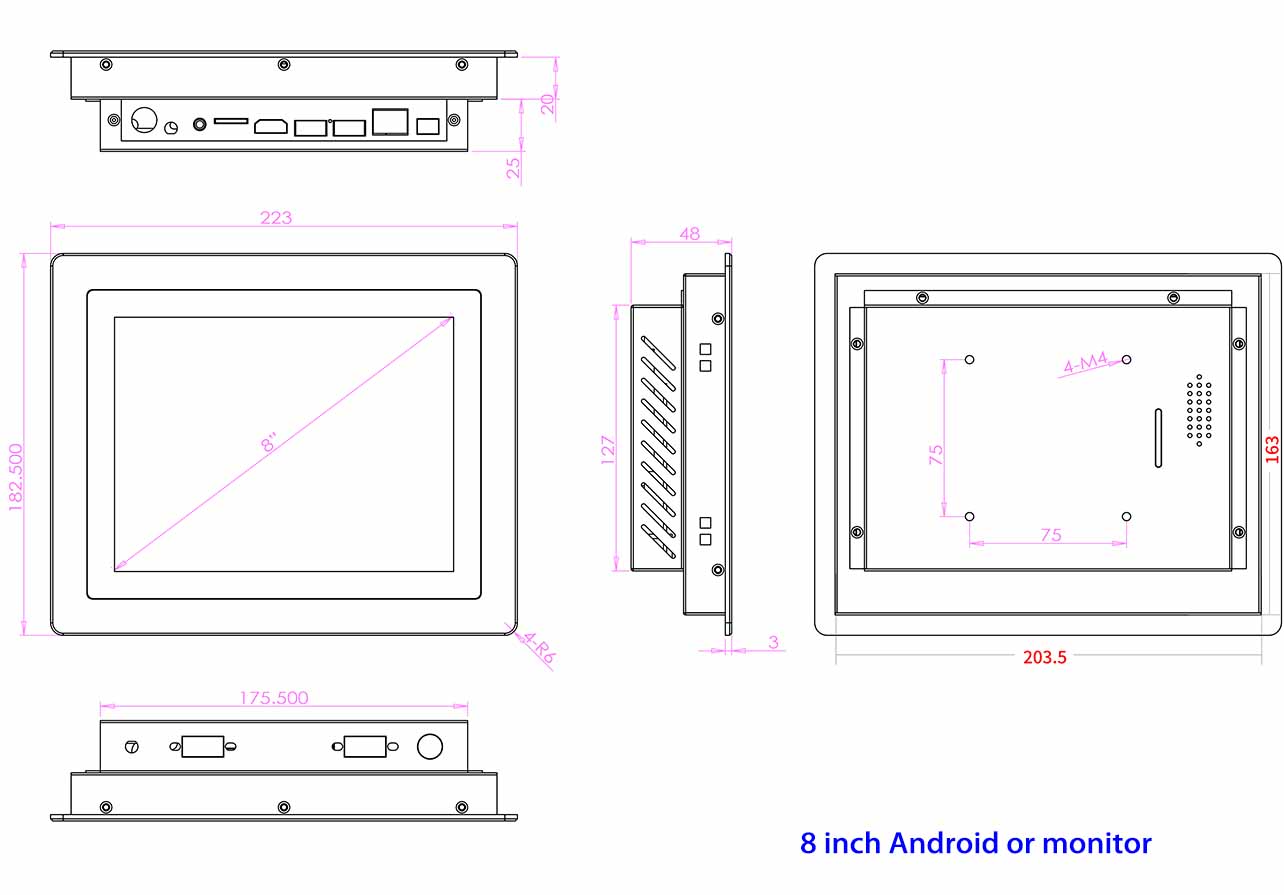

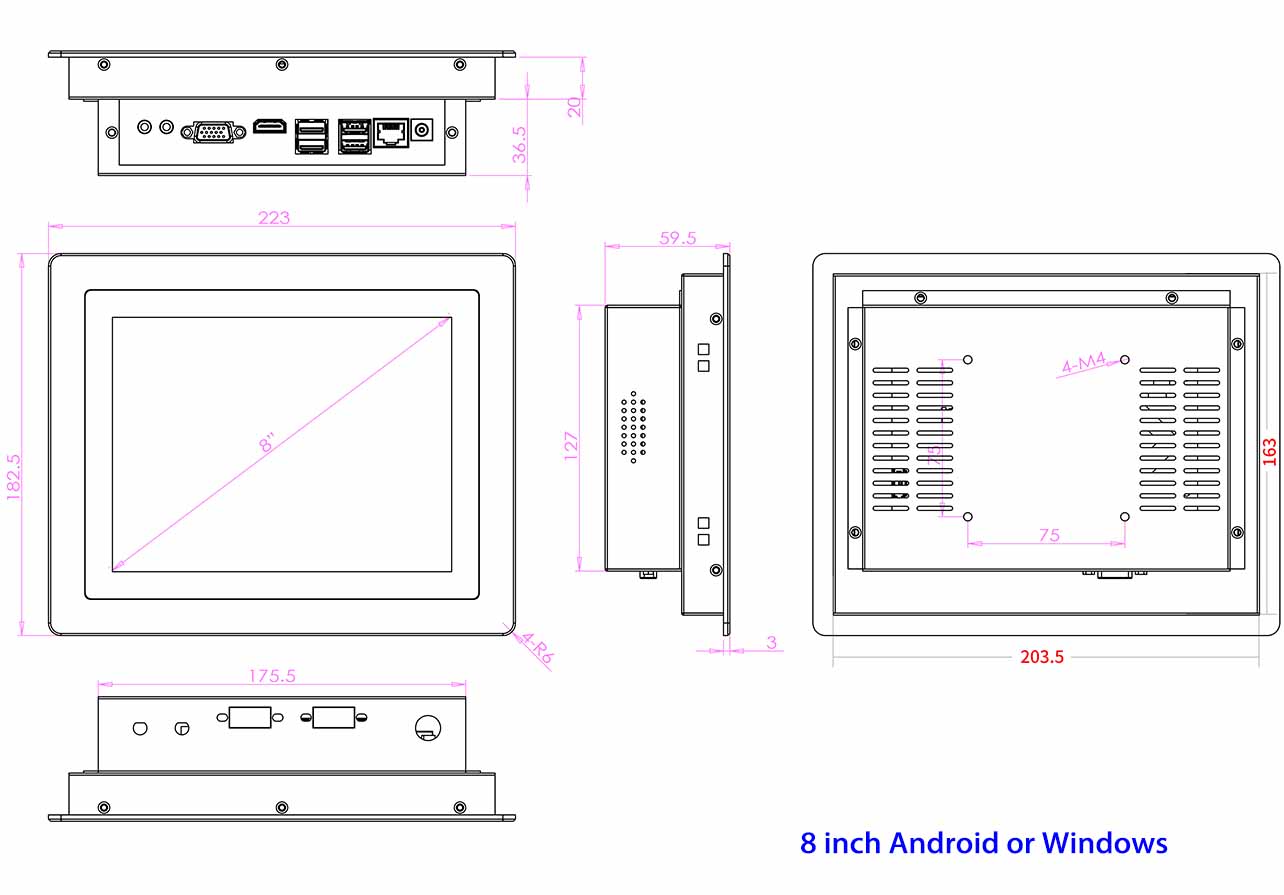

Micro embedded industrial tablet computer integrated intensive design, effective and reasonable use of space, support desktop, wall hanging, embedded, open and other installation methods, support a variety of expansion, powerful enhancement of the industrial tablet computer computing power and control ability, can fully solve the problems that need to be solved by automatic packaging.

Industrial tablet computer packaging code implementation:

With the rapid development of modern industry and the improvement of the degree of automation of packaging equipment, the requirements of packaging and identification of products are more and more complex. In particular, food, beverage, tobacco, alcohol, medicine and cosmetics packaging printing enterprises need to frequently or high-speed digital, bar code, pattern or text printing on the outer packaging or other items, users need to edit, set and change the content of the printing according to their own requirements, which makes the high performance injet equipment with man-machine interface has been more and more widely used. WinCE/ Android embedded operating system is the best solution to meet the demand.

For packaging machinery, different ingredients, different packaging materials, different packaging containers and other packaging requirements. In the packaging process, the control system needs to make the machine high-speed, accurate and stable operation. Provide the accurate position of the machine to correct the error caused by friction or vibration during the transmission process.

Industrial tablet computer in its powerful processing capacity, can accurately handle different packaging instructions, and in the production speed, mechanical performance, noise pollution and other indicators, are the previous machinery can not be matched.

Today, the need for highly flexible operation and continuous drive to maximize capacity presents great challenges and opportunities for suppliers. New motion control products are becoming more powerful and compact, and new architectures can provide comprehensive technical solutions for a wider range of packaging machinery applications.

Here is a series of application profiles to show the continued progress of automation and motion control solutions and the increasingly better overall solutions available for packaging machinery.

Solutions for Industrial Tablets:

Automatic packaging is a very complex process, even in the era of manual packaging, packaging work also needs to go through multiple processes. Including but not limited to weighing, sorting, film shrinkage (inner packaging)/filling, coding, packing and other steps.

This requires industrial tablets to have strong computing power and control ability.

Micro embedded industrial tablet computer integrated intensive design, effective and reasonable use of space, support desktop, wall hanging, embedded, open and other installation methods, support a variety of expansion, powerful enhancement of the industrial tablet computer computing power and control ability, can fully solve the problems that need to be solved by automatic packaging.

Industrial tablet computer packaging code implementation:

With the rapid development of modern industry and the improvement of the degree of automation of packaging equipment, the requirements of packaging and identification of products are more and more complex. In particular, food, beverage, tobacco, alcohol, medicine and cosmetics packaging printing enterprises need to frequently or high-speed digital, bar code, pattern or text printing on the outer packaging or other items, users need to edit, set and change the content of the printing according to their own requirements, which makes the high performance injet equipment with man-machine interface has been more and more widely used. WinCE/ Android embedded operating system is the best solution to meet the demand.