10 "Android industrial tablets and MES applications in fact

With the convening of China's Industry 4.0 and "China Intelligent Manufacturing 2025", it is urgent for large manufacturing enterprises to upgrade manufacturing, build smart factories, improve production efficiency, reduce costs, and improve quality and service. To realize intelligent manufacturing, it is necessary to completely solve the problem of transparency of low value-added production process, so that enterprises can first vertically series, and data can pass through seamlessly, so as to realize scientific analysis and decision-making based on data acquisition, and realize intelligent and automated management.

System requirements:

To realize intelligent manufacturing, for manufacturing enterprises, it is to make the production process with low added value transparent, so that the enterprise is connected and the data is uploaded to the cloud application layer. At the same time, the whole workshop production process can be visualized and informationized.

Workshop informatization and visualization, mainly through solving two kinds of problems: one is to solve the on-site production progress dispatch, work report, data information upload, the other is to solve the on-site safety production progress monitoring system problem analysis and visualization.

Based on the on-site environment of the factory, Weinset Gaochi Company recommends solutions suitable for enterprises to solve the problems of the current intelligent factory:

First, in view of the hot summer workshop temperature can reach more than 50 degrees, dust, oil pollution environment, it is necessary to real-time connection of each station data with MES system.

Solution:

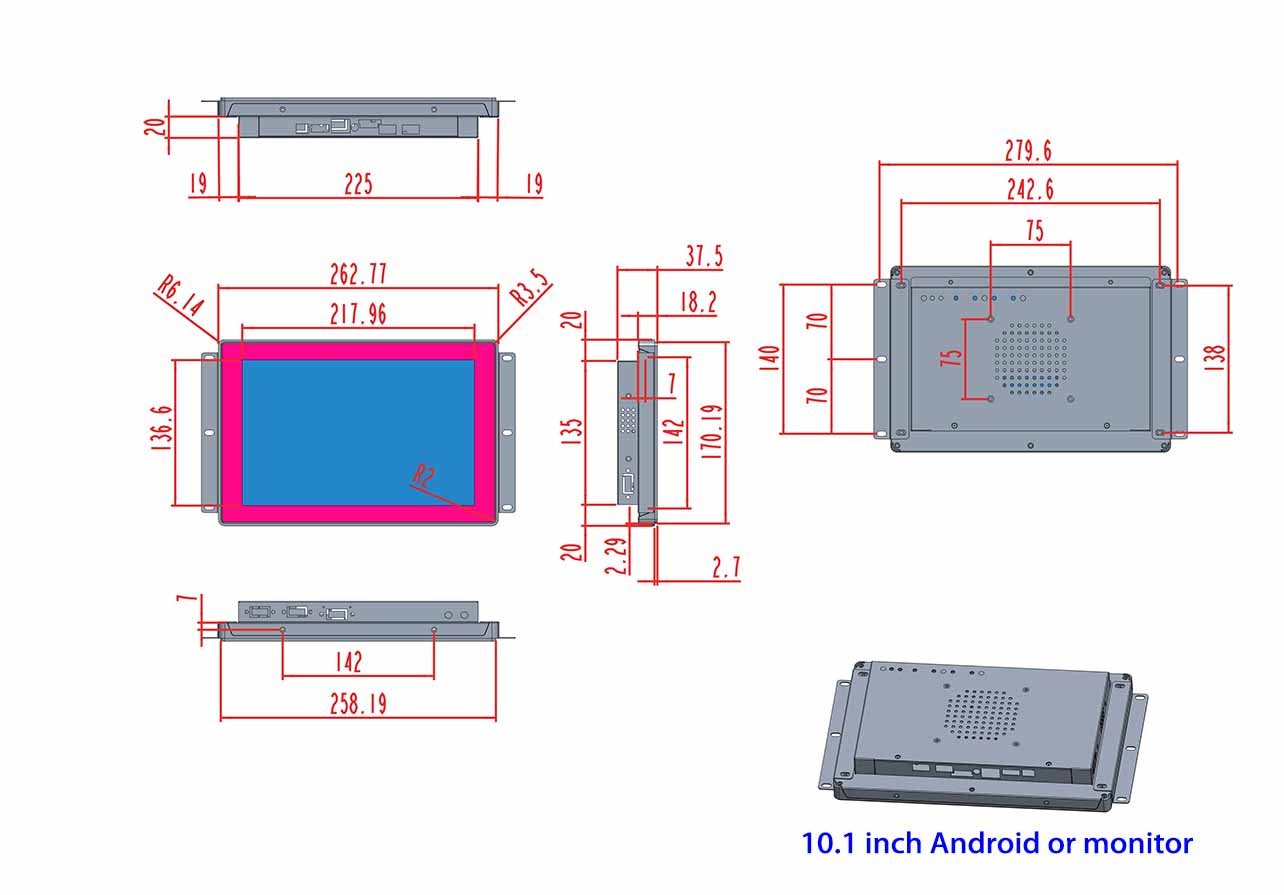

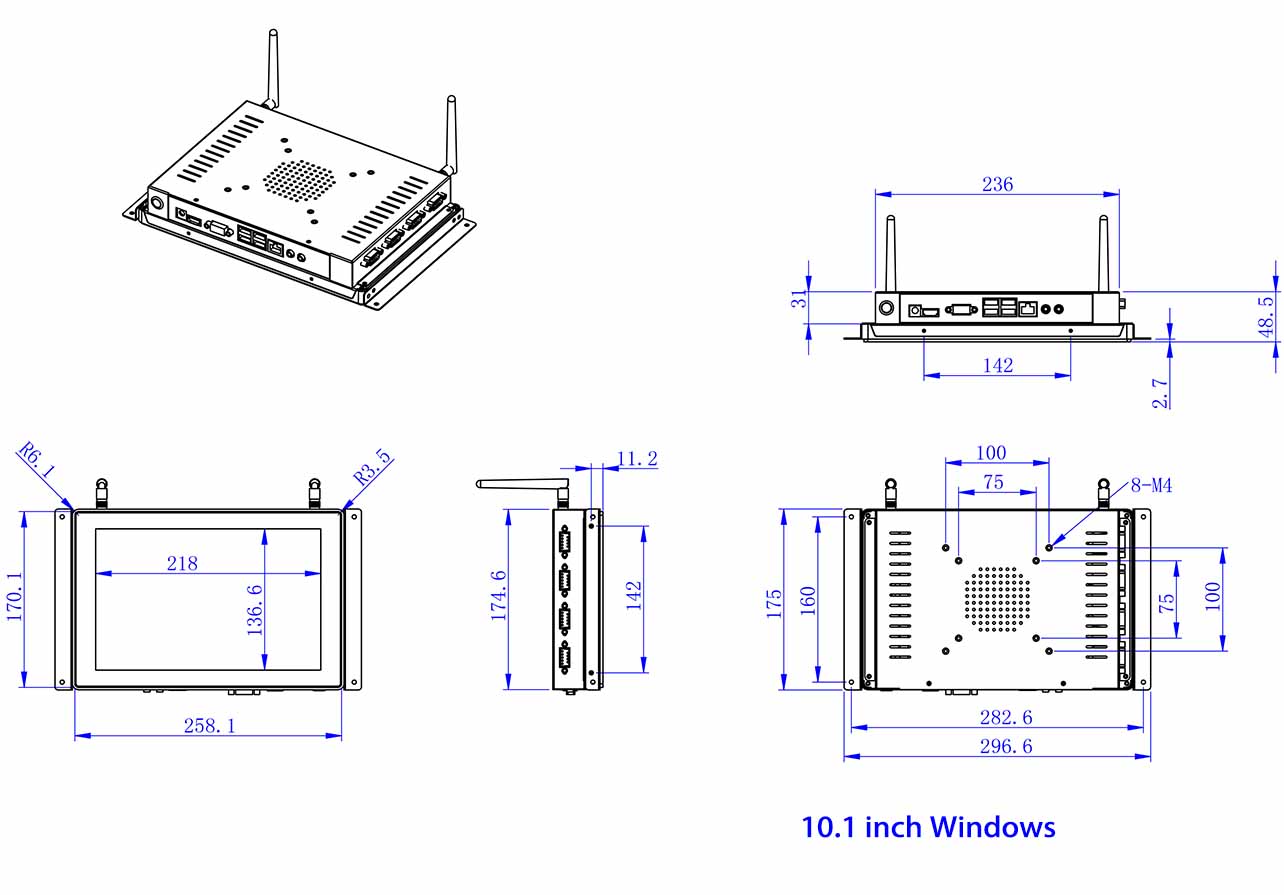

The use of Guangzhou micro embedded industrial tablet computer WAR-101C-RM10, working environment temperature can reach -10~60 degrees Celsius, can fully cope with the summer high temperature field environment, rich interface can meet the needs of different types of developers, so that the core board of data transmission and expansion can be extremely good play. Loading the MES software developed by the user can realize the quick browsing of the day's technology and dispatch situation on the station, complete the report in real time according to the production progress, and upload the information synchronously. Workers on site only need to produce according to the dispatch of intelligent terminal equipment, and then report work.

2. Visualization of on-site production progress monitoring problems.

Solution:

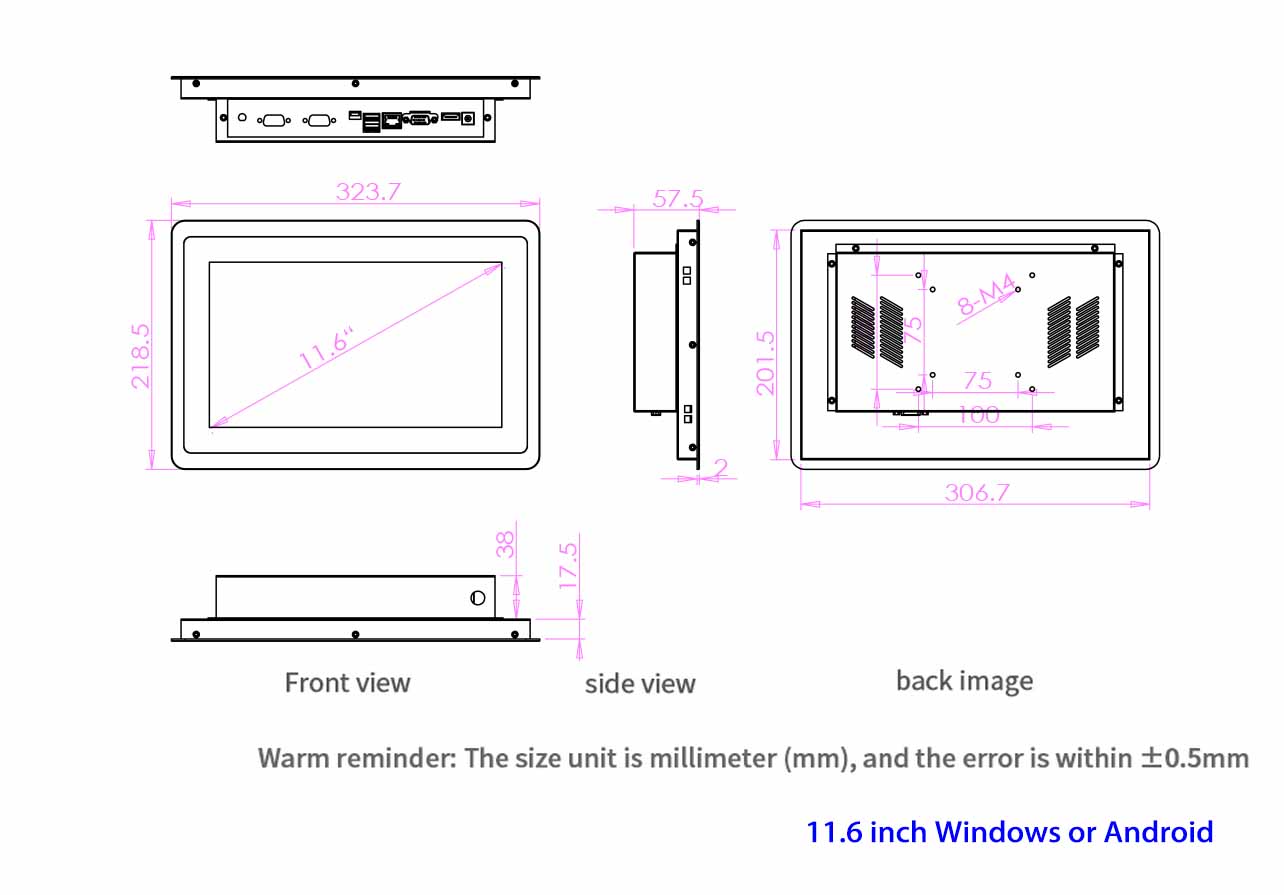

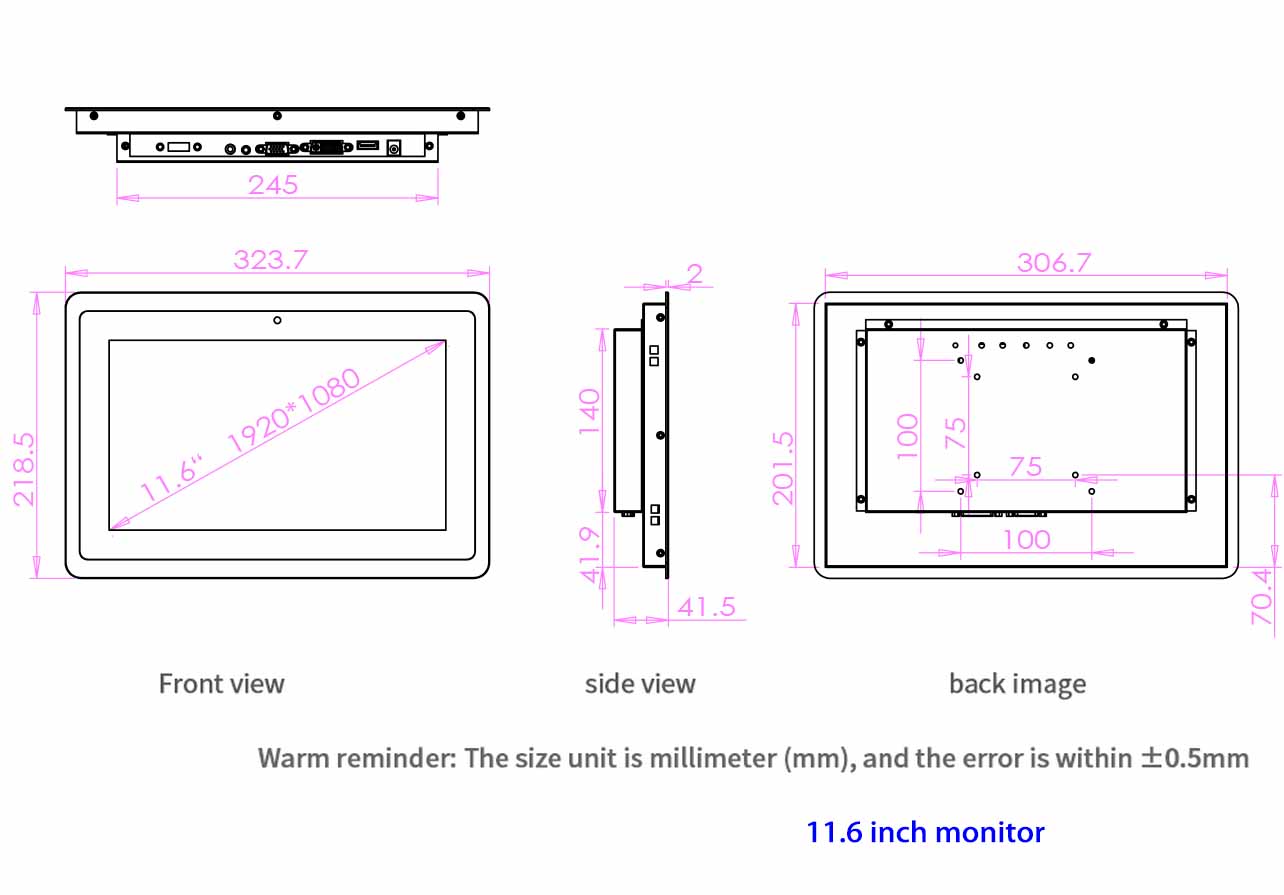

The MES system is loaded and run by WAR-VGA of Guangzhou micro embedded industrial computer. Through VGA or HDMI display interface connected to the large screen, the production progress, target completion, product quality, as well as the utilization of people, machines and materials in the production site can be presented in real time through the system report, so that the entire production site is completely transparent and visual.

Customer benefits:

Guangzhou micro embedded terminal according to the customer production workshop manufacturing station, seamless docking with the company's MES system, so that it is convenient to facilitate the operation of workers, but also the production progress on the electronic board display, greatly improve productivity.

System requirements:

To realize intelligent manufacturing, for manufacturing enterprises, it is to make the production process with low added value transparent, so that the enterprise is connected and the data is uploaded to the cloud application layer. At the same time, the whole workshop production process can be visualized and informationized.

Workshop informatization and visualization, mainly through solving two kinds of problems: one is to solve the on-site production progress dispatch, work report, data information upload, the other is to solve the on-site safety production progress monitoring system problem analysis and visualization.

Based on the on-site environment of the factory, Weinset Gaochi Company recommends solutions suitable for enterprises to solve the problems of the current intelligent factory:

First, in view of the hot summer workshop temperature can reach more than 50 degrees, dust, oil pollution environment, it is necessary to real-time connection of each station data with MES system.

Solution:

The use of Guangzhou micro embedded industrial tablet computer WAR-101C-RM10, working environment temperature can reach -10~60 degrees Celsius, can fully cope with the summer high temperature field environment, rich interface can meet the needs of different types of developers, so that the core board of data transmission and expansion can be extremely good play. Loading the MES software developed by the user can realize the quick browsing of the day's technology and dispatch situation on the station, complete the report in real time according to the production progress, and upload the information synchronously. Workers on site only need to produce according to the dispatch of intelligent terminal equipment, and then report work.

2. Visualization of on-site production progress monitoring problems.

Solution:

The MES system is loaded and run by WAR-VGA of Guangzhou micro embedded industrial computer. Through VGA or HDMI display interface connected to the large screen, the production progress, target completion, product quality, as well as the utilization of people, machines and materials in the production site can be presented in real time through the system report, so that the entire production site is completely transparent and visual.

Customer benefits:

Guangzhou micro embedded terminal according to the customer production workshop manufacturing station, seamless docking with the company's MES system, so that it is convenient to facilitate the operation of workers, but also the production progress on the electronic board display, greatly improve productivity.